Lens Options

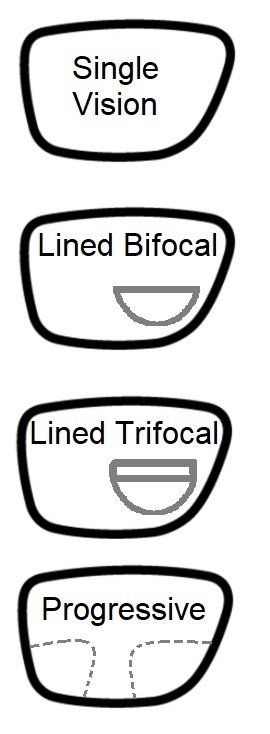

Single Vision

Single vision lenses are used to correct astigmatism, nearsightedness, farsightedness and presbyopia for one distance. The correction is the same throughout the whole lens. For younger patients these types of lenses are worn all the time or for specific tasks (i.e. computer glasses). For older patients (> 40 years) they will use them for either distance, intermediate or near. The distance chosen is based on the patient's prescription and their individual needs. Single vision lenses are the common type of lenses used.

Multifocal Lenses

Multifocal lenses are usually used for those over the age of 40 who have lost the ability to focus on objects at near distances or presbyopia. These lenses include lined bifocals, lined trifocals and progressives. They provide vision at multiple distances.

Lined Bifocals

A lined bifocal typically provides distance vision and one set near distance. There are three commonly used types of bifocals. They include a flat-top 28 (FT-28), flat top 35 (FT-35) and an executive. The FT-28 has a 28 mm wide segment and the FT-35 has a 35 mm wide segment. The executive goes all the way across the bottom of the lens. The wider FT-35 and executive lenses give more working room.

Lined Trifocals

Trifocal lenses provide distance, fixed intermediate (computer) and fixed near vision (reading). Common types of trifocals include a 7 x 28, 7 x 35, 8 x 35 or an Executive. The 7x28 and 7 x35 lenses have an intermediate portion that is 7 mm in height and widths of 28 mm and 35 mm. The 8 x 35 has an intermediate segment that is 8 mm in height and 35 mm in width. The executive lens has an intermediate and lower segment that go across the entire lens.

Progressives (No-line Bifocals)

Progressive lenses provide clear vision at any given distance that is viewed and doesn't have any apparent line (no-line bifocals). They have a “corridor” or “channel” of clear vision that increases in plus power as an individual looks down through their glasses. The “channel” proceeds down and slightly in. A drawback of the lens is that when an individual looks down and in or out their vision is distorted because of the way the lens had to be designed. It is very common to have a period of adaptation when getting them for the first time. Digital progressives are individually made. They will have a wider portion of the lens that is useful and are easier to adapt to.

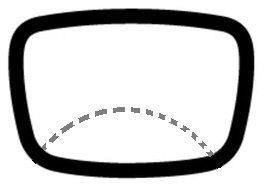

Anti-Fatigue Lenses

Anti-fatigue lenses have a small "boost" of near or add power to lessen eye fatigue and strain when looking between far and near. The boosted portion of the lens is not noticeable when the lens is worn. These types of lenses help those with digital eye fatigue from spending a lot of time on the computer and "emerging presbyopes" that are starting to have problems seeing up close. The powers for the near portion are usually less than an add of +1.00 and it has the shape of a setting sun.

Lens Materials

CR-39

CR-39 or a traditional plastic lens is the most widely available material and has the most lens options. It has low light dispersion and relatively good optics. However, it requires the addition of scratch resistant and UV coatings. For mild to moderate prescriptions its weight and thickness are acceptable, however, in high prescriptions it is better to use a lighter and higher index material. It cannot be used in safety frames or drill mounted lenses because of its poor impact resistance. Use in semi-rimless frames is possible, but the lens is more likely to chip as it is grooved and used. There are fewer reflections off the surface of a lens with CR-39 than most materials. An uncoated CR-39 lens is the best option for tinting lenses.

Polycarbonate

Polycarbonate is a very light and impact resistant lens material. It comes with a scratch resistant coating and inherently blocks UV light. It is a good material for use with drill mounted, semi-rimless and safety lenses. It is the standard material used in safety glasses because of its impact resistance. It has more light dispersion than a traditional plastic lens, which causes some adaptation issues in a few patients because of color fringes that may be seen. Polycarbonate has the second most available lens options and is more expensive than traditional plastic. The use of an anti-reflective coating is highly recommended to limit dispersion and glare.

Trivex

Trivex (proprietary brand is known as

Phoenix) is the newest material available for use in ophthalmic lenses. It is the lightest material available, most impact resistant, inherently blocks UV light and comes with a scratch resistant coating. It is the best material for use with drill mounted, semi-rimless and safety frames. The tensile strength of trivex makes it highly resistant to cracking around drill holes and is the best material for that or any high-end fashion frame that depends on the lens to hold its shape. It has less dispersion than most lenses and good optical qualities. Because it is relatively new, it has less lens options and is more expensive. With high prescriptions it will be thicker than polycarbonate or higher index materials.

Hi-Index

Hi-index lenses can refract light better with less material. They were created to reduce the thickness and weight of lenses with high prescriptions. They should mainly be used for that purpose only. In really high prescriptions these materials can make a huge difference. For prescriptions between +/- 6.00 and +/- 10.00 prescriptions hi-index materials should be used and for prescriptions greater than +/- 10.00 ultra hi-index materials should be used

Hi-index materials can be tinted and are acceptable for drill mount frames. They are inherently UV protective and come with a scratch coat. Reflections off the lens surfaces are high and are strongly recommended that they come with a quality anti-reflective coating.

Crown Glass

Crown glass is rarely used to make prescription lenses now. The reason behind this has to do with the weight of the lenses and potential of eye injury from impact. The lenses can crack and cut the eye. Heat/chemically treated lenses offer increased protection, but if they are scratched, they have been compromised. Crown glass lenses do have incredible optics and very low light dispersion. They are usually specially ordered and are seen in high end sunglass frames.

Lens Additions

Anti-Reflective Coatings

Anti-reflective (AR) coatings are a microscopic layer of a special material applied to lenses that reduces the amount of glare that comes off of them. They give a lens a green or purple sheen. AR coatings are most beneficial for those who work on a computer screen all day and for those with difficulty driving at night or who frequently drive at night. An AR coating is also more beneficial for high index lenses because of increased surface reflections and polycarbonate lenses because of high dispersion. A good AR coat can increase light transmission into the upper 90% range.

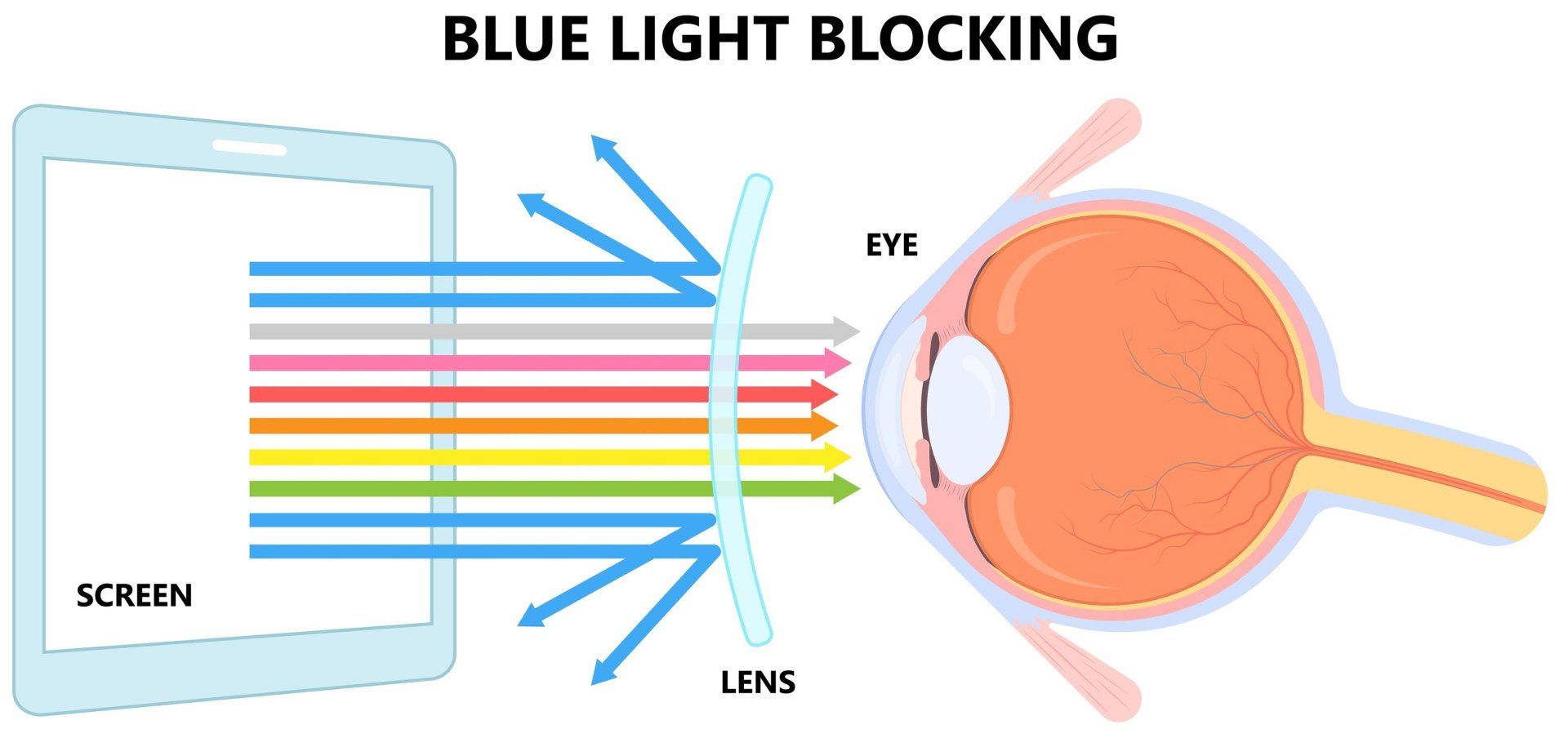

Blue Blocking

Blue blocking lenses block the transmission of blue light from going through our lenses and thus entering into our eyes. In some cases it is put into an anti-reflective coating and in others it is incorporated into the lens material. Research indicates that blue blocking lenses do not help with digital eye fatigue or eye strain (a mild plus prescription can help) However, it does indicate that these types of lenses help to maintain a good sleep-wake cycle. They help you fall and stay asleep when working on our digital devices prior to falling asleep. Adding blue blocking to any pair of glasses that will be used while working on computers, tablets or smartphones is recommended.

Mirror Coatings

Mirror coatings enhance use and style with sports eyewear and sunglasses. They are designed to minimize extreme glare associated with water, snow and sun activities. These coatings decrease the light transmission in a lens thereby minimizing a high intensity amount of light from reaching the eyes. Another element is the "cool" cosmetic look that's associated with eyewear that has mirror coatings.

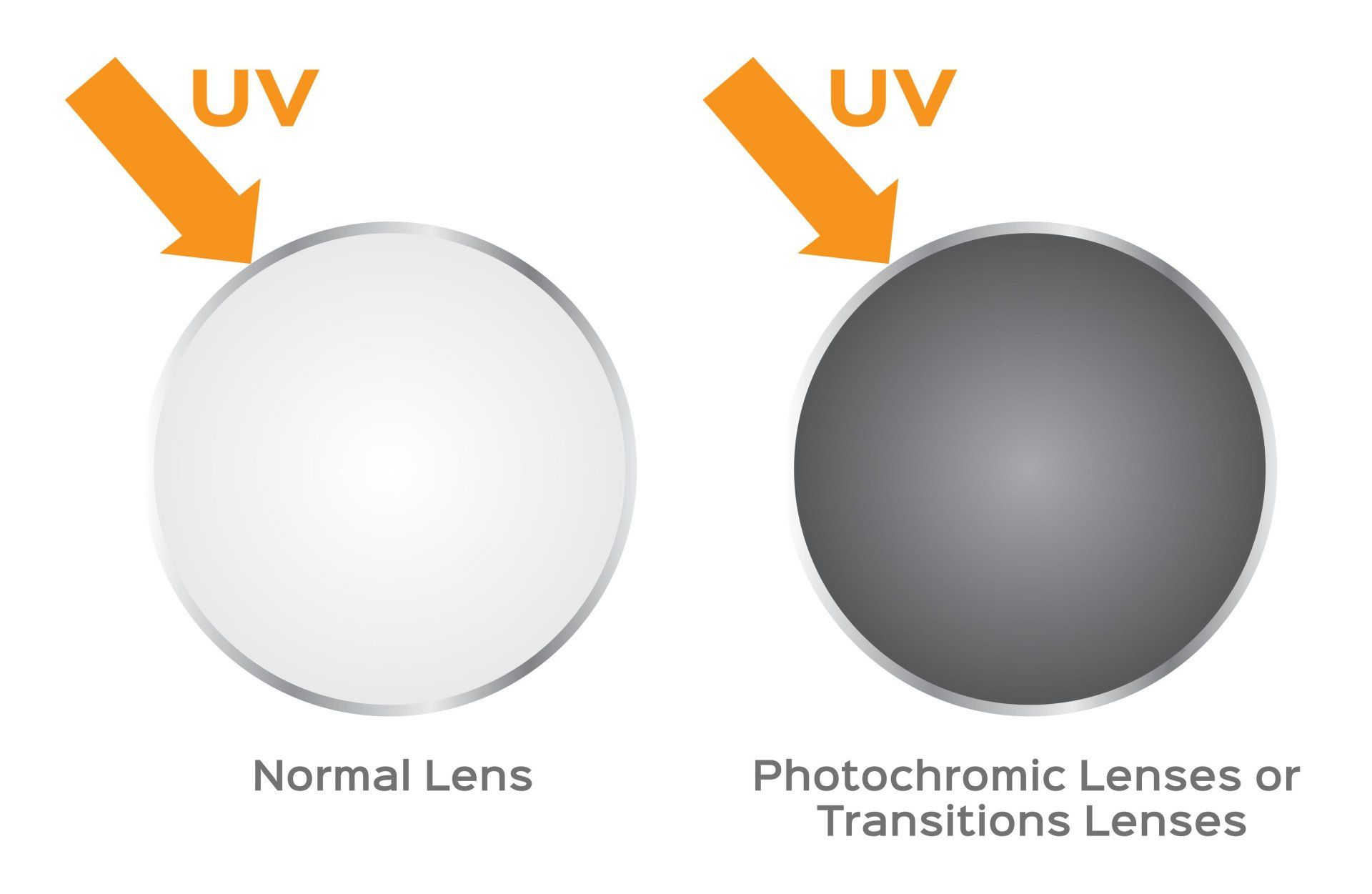

Photochromic Lenses

Photochromic lenses have a photochromic material incorporated into the lens matrix that darkens when exposed to ultraviolet (UV) light. These lenses are clear when indoors and not exposed to UV light; however, when they are taken outside they act like a sunglass lens and darken because of exposure to the UV light. A drawback to these lenses is that they don’t work well in a vehicle because most vehicle windows absorb UV light. A popular name brand of photochromic lenses is “Transitions.”

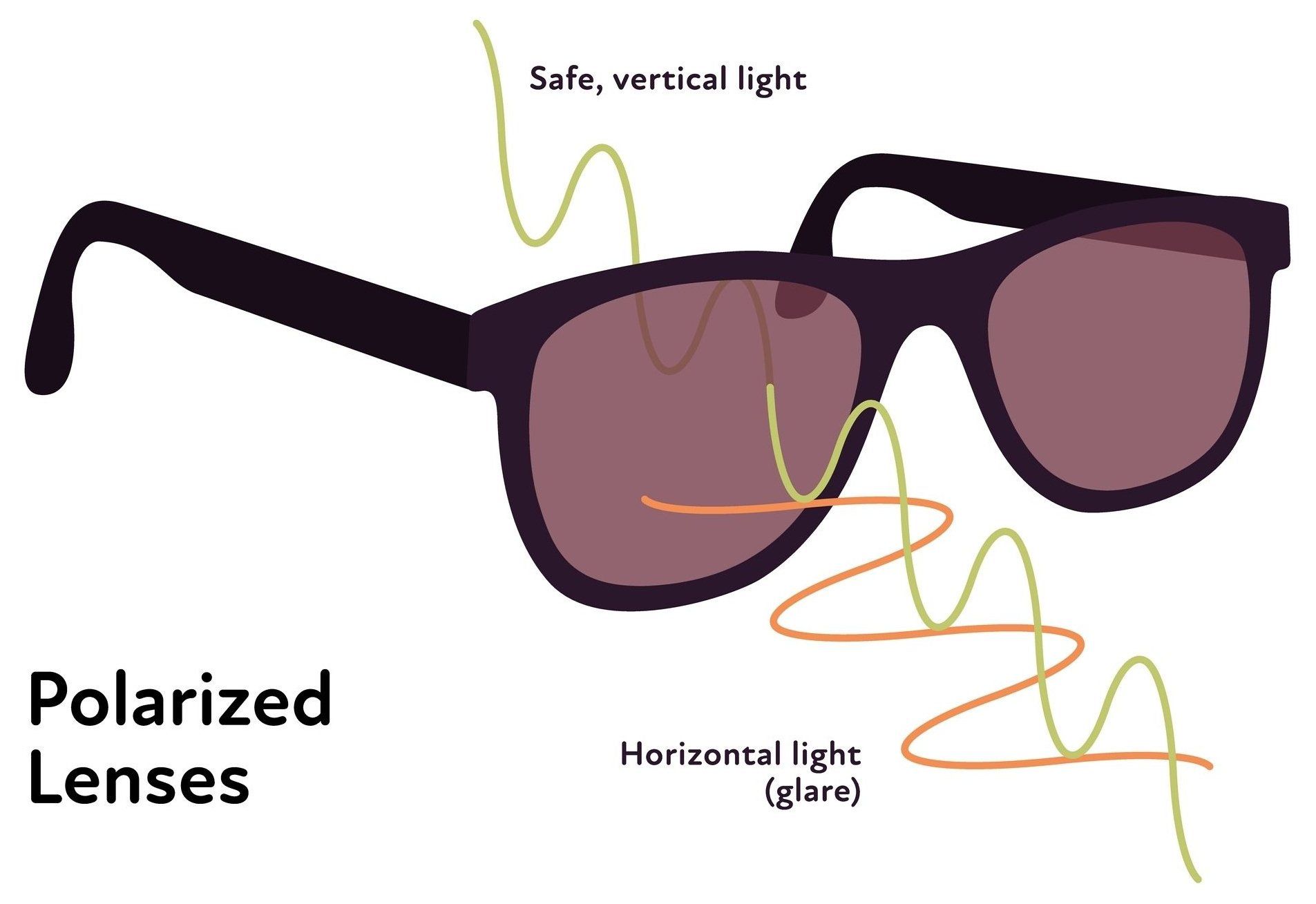

Polarized Lenses

Normal light is un-polarized meaning its electromagnetic fields’ orientation is in many directions. With the use of polarizing filters it can become polarized where the electromagnetic field’s orientation is only in one direction. This can be very beneficial for sunglasses because they can reduce a significant amount of glare without degrading image quality. These lenses are ideal for water sports and driving because of the way light reflects off of the road and water. Common colors of polarized lenses are brown, gray and olive. Polarized lenses are the very best option for sunglasses.

Tints

Tints absorb light to decrease the intensity of incoming light. They are often used in sunglasses to give a unique look and therapeutically. They come in many different colors and enhance vision in certain activities (i.e. a yellow tint for playing golf or driving). Gradient tints are available where the top portion of the lens is tinted but lightens as you go down the lens. They are good for golfers that want a sunglass option for playing golf, but a clear portion when reading their score card. A specific tint called FL-41 (a rose pink color) has been shown to help some people with migraine headaches and light sensitivity. Yellow lenses are also used to enhance video gaming (i.e. Gunnar Lenses).

Frame Materials

Eyeglass frames are commonly made of three different types of material that include metal, zyl (plastic) and nylon.

- Metal frames are made from nickel/nickel-plated, stainless steel, titanium or aluminum. Most metal frames are made with adjustable nose-pads.

- Nickel/Nickel-Plated: these types of frames are inexpensive, durable and light; but some people are allergic to the nickel and get rashes when the frame contacts the skin and they get a green build on the frame (body acids react with the nickel material on the temples and nose pieces)

- Stainless Steel: this material is hypoallergenic, strong and light; however, it is more expensive

- Titanium: this is the best metal material for a frame, it is hypoallergenic and very lightweight; but is also the most expensive

- Memory Metal: this metal alloy was developed to bend and return to its original shape, they are very lightweight, hypo-allergenic and corrosion resistant

- Aluminum: it is rarely used in eyeglass frames, but it is lightweight and corrosion resistant

- Zyl is a plastic material that many frames are made of. It is corrosion resistant and hypoallergenic. It can be made in many shapes and forms. The color options with zyl frames are almost limitless and it is inexpensive. Most zyl frames do not have adjustable nose pads, however, they can be added.

- Nylon frames are similar to plastic frames, but they are much more durable and expensive. It is used in a lot of sport and high end frames.

Frame Designs

Full Eye Wire

A full eye wire frame has a rim 360 degrees around the lens. This is the most common type of frame. With lenses that have a thick edge (high Rx) this type of frame is the best. It can help to hide the thickness and holds the lens in place the best. This type of frame is made out of any type of material.

Semi-Rimless

A semi-rimless frame usually has a rim that goes around the frame 180 degrees and then is held in place with a plastic wire around the other 180 degrees. Most frames have the rimless portion on the bottom of the frame, but some have no frame on the top. For the lens to be held in place a groove is cut along the entire circumference of the lens. Polycarbonate and Trivex are the most durable materials for this.

Rimless

In rimless frames there is no rim on any portion of the frame. Instead the temples and nose pieces are connected to the frame with drilled holes and plastic plugs. The lenses become a part of the frame. These frames are very fashionable and light. However, they need to be handled carefully. Titanium and stainless steel are sturdy materials for these frames. Trivex should be used with this type of frame due to its incredible durability.

Eyeglass Measurements

Frame Measurements

An advantage to purchasing eyewear at an eye doctor's office is that you can try on the eyeglass frames prior to purchasing them. How frames fit will vary from person to person. When considering what frame to use prior to purchasing them, there are three measurements that you should consider. They include the lens size, bridge width and temple length. The lens size is the biggest consideration when determining frame width. The accompanying diagram shows lens sizes to consider based on the size of the head. The temple length is used to see how the frame will fit behind the ear. A frame's temple piece should extend behind the ear to just above the earlobe.

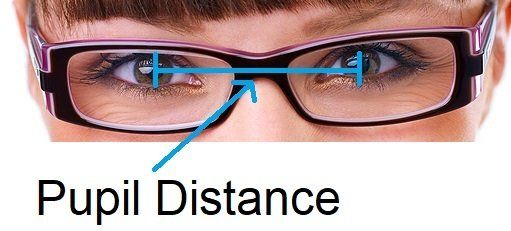

Pupil Distance

An important measurement when getting a new pair of glasses is called the pupil distance (PD). It is the horizontal measurement of the distance between your eyes. It can be tricky to measure it by yourself. It will be given as binocular or monocular measurements. For adults the binocular PD can range from 54 - 72 mm. In children it can range from 42- 58 mm.

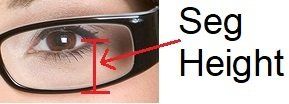

Seg Height & Ocular Center

The ocular center or seg height are vertical measurements measured from the lowest part of the frame. For high prescriptions and progressive lenses the ocular center and seg height are made from the center of the pupil. With lined multifocals they are at the lower lid or slightly higher. This measurement is unique to how different glasses fit on different people. It can't be measured without the wearer actually wearing the frame.